Sapal SA

Avenue du Tir-Fédéral 44

1024 Ecublens

Switzerland

+41 21 633 53 00

Hotline Service : +41 21 633 54 44

© Sapal SA copyright 2021 – design & powered by stanprod

In a world where efficiency, flexibility, and sustainability have become essential, remote FAT (Factory Acceptance Test) stands out as an innovative and advantageous solution.

We usually welcome our clients or their representatives at our production site in Écublens to carry out the FAT, a crucial step aimed at verifying that the delivered equipment fully meets the client’s technical requirements.

However, in 2020, during the height of the health crisis, travel was impossible. We therefore quickly implemented an alternative:

the remote FAT, conducted live.

Since then, this method has proven to be extremely beneficial, offering three major advantages :

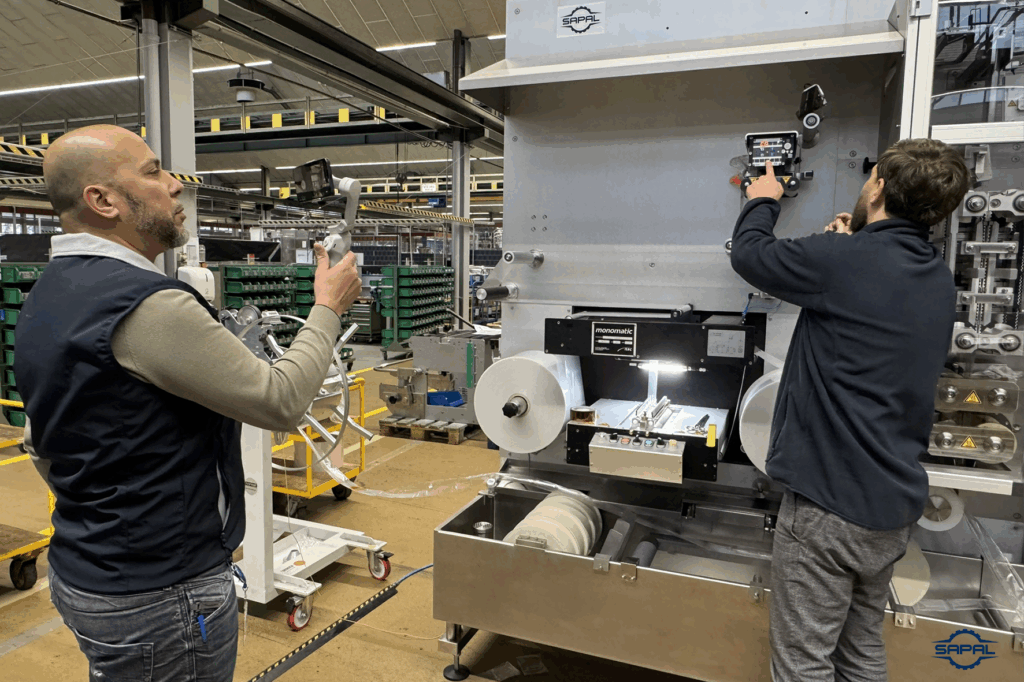

During these virtual FATs, a project manager and an engineer test each machine component in real time. All steps are demonstrated and explained live, with a Q&A session to ensure every detail is clear and validated.

This time, the FAT involved a DCS 1000-2, a packaging machine dedicated to slices of processed cheese. We thank our client for their trust and collaboration.🙏

Ready to bring your vision to life?

Our team of talented designers and experienced project managers will support you every step of the way.

Let’s discuss your ideas—we’ll provide you with a personalized quote tailored to your needs.

We are here to transform your concepts into cutting-edge automated solutions.

Sapal SA

Avenue du Tir-Fédéral 44

1024 Ecublens

Switzerland

+41 21 633 53 00

Hotline Service : +41 21 633 54 44

© Sapal SA copyright 2021 – design & powered by stanprod

Sapal SA

Avenue du Tir-Fédéral 44

1024 Ecublens

Switzerland

+41 21 633 53 00

Hotline Service : +41 21 633 54 44

© Sapal SA copyright 2021 – design & powered by stanprod

Nous utilisons des cookies pour améliorer votre expérience de navigation, analyser le trafic du site et soutenir nos actions marketing. En continuant à utiliser notre site, vous acceptez l’utilisation de cookies. Pour en savoir plus, veuillez consulter notre Politique de confidentialité.